Sophisticated Inspection Tool using Scanned Point Cloud Data

Sophisticated Inspection Tool using Scanned Point Cloud Data

spGauge is an inspection software which uses point cloud data, measured by a 3D scanner, and CAD design data. spGauge is utilized during the production preparation stage in manufacturing as well as in the prototyping and mass production stages.

HOME > spGauge

01/04

Drastically Reduce Prototyping and Production Preparation Time

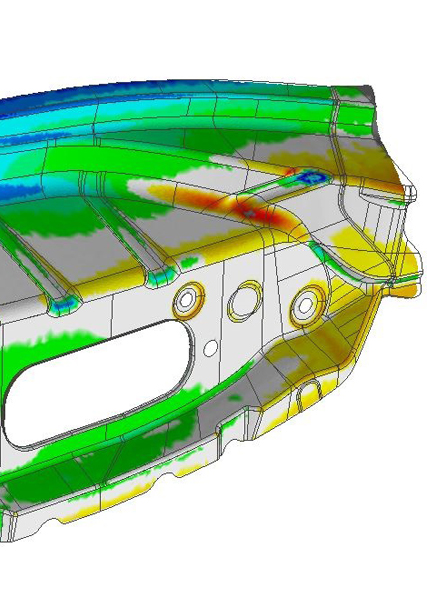

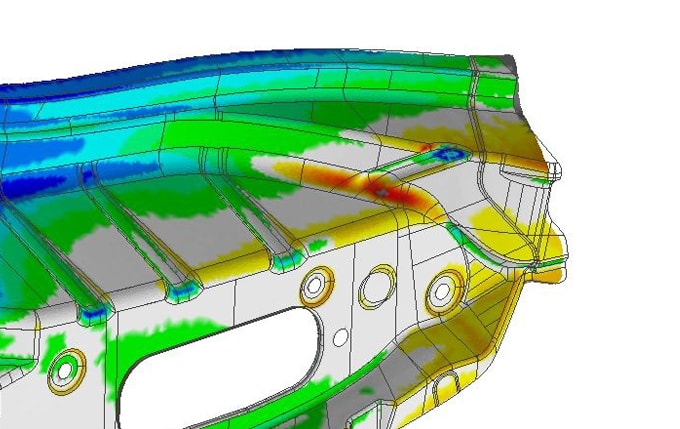

You can use the color map to visually review erroneous part between the point cloud data measured by non-contact digitizer and the 3D CAD model data.

Furthermore, you can also effortlessly review the parts that are not satisfying the tolerance values by computing dimensions from point cloud data measured by the non-contact digitizer.

The overall man-hours spent on manufacturing can be reduced by majorly reducing the time for developing prototypes and preparing products by using the non-contact measurement machine, that can scan the surface shape of products and molds/dies, as well as the inspection software "spGauge."

02/04

Alignment that Actualizes a Desired Result

Alignment is the most important feature when it comes to comparing point cloud data and 3D CAD data.

In order to gain a trustworthy inspection result, you must accurately align the point cloud data part that is to become the inspection reference.

By accurately aligning point cloud and 3D CAD data, you can obtain the same inspection results through spGauge as that of conventional inspection jigs.

Furthermore, regardless of point cloud and 3D CAD data, it is also possible to align the master product and of the scanning target point cloud data.

spGauge can perform optimal alignment according to each purpose based upon the experiences and techniques built up in the manufacturing setting.

03/04

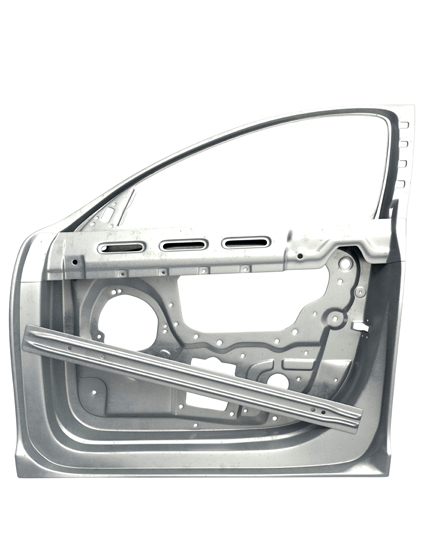

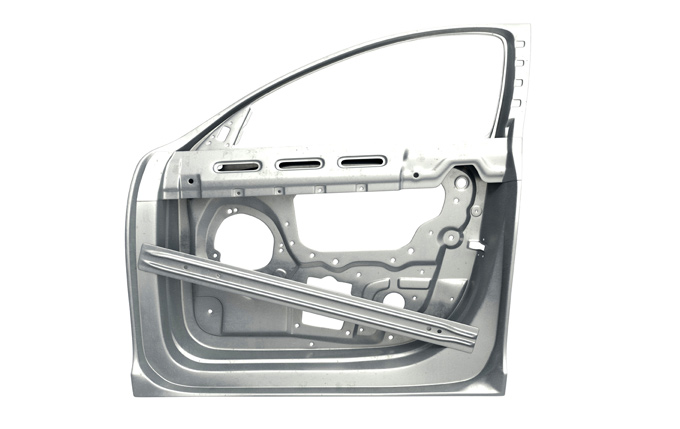

Extensive Inspection Features Dedicated for Metal Stamping

Comes equipped with a function that can automatically and accurately extract holes, plate stops, plate thickness, and welding points in pressed products.

Holes and endshapes are extracted after excluding jigs or the bottom point cloud data, which are not part of the inspection target.

The panel-thickness inspection result can be visually reviewed using the color map to check the panel-thickness reduction ratio or the locations of wrinkles.

In welding point inspection, it is possible to detect the alignment's positional shift against the configured value, by identifying the welding part's recess (indention). This inspection frees up massive man-hours spent on humans reviewing each and every welding point as well as solving the likelihood of inspection oversights. Furthermore, utilizing spGauge makes it easier to follow inspection records and thereby enhances traceability measures.

04/04

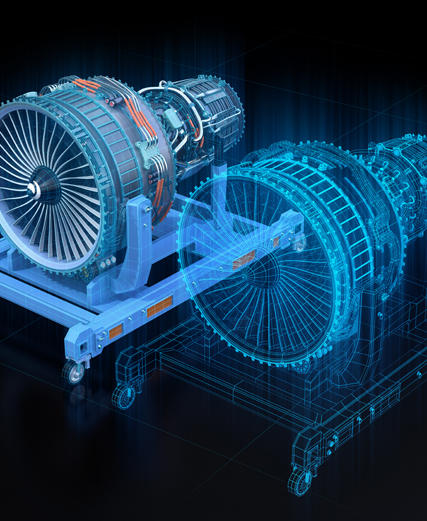

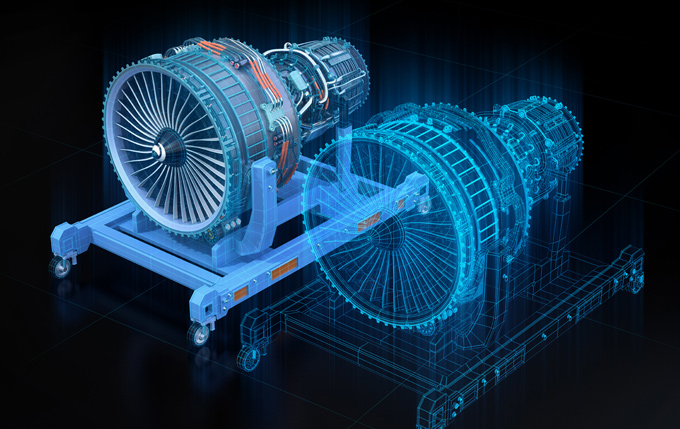

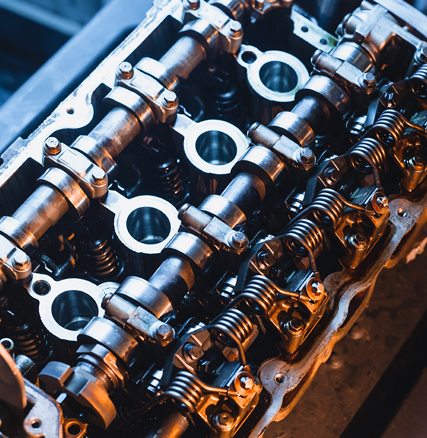

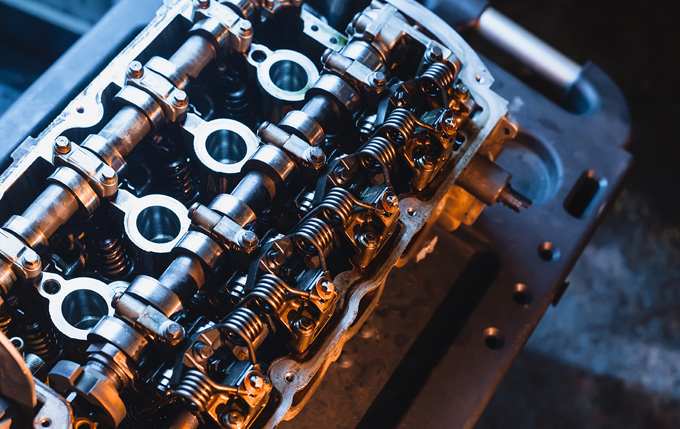

Detects Thickness of a Cast Product within a Brief Time

Based on the non-contact measurement point cloud data of a cast product, spGauge displays the thickness value of each part using color map or contour line to detect the areas that do not meet the assured thickness.

Even complex shaped parts such as engine blocks can be inspected in a short time without any oversights. This is a very powerful feature that is useful when doing prototype inspections at the massive production preparation stage.