Features

Inspecting for Exact Same Hole Shapes as Actual Stamped Product

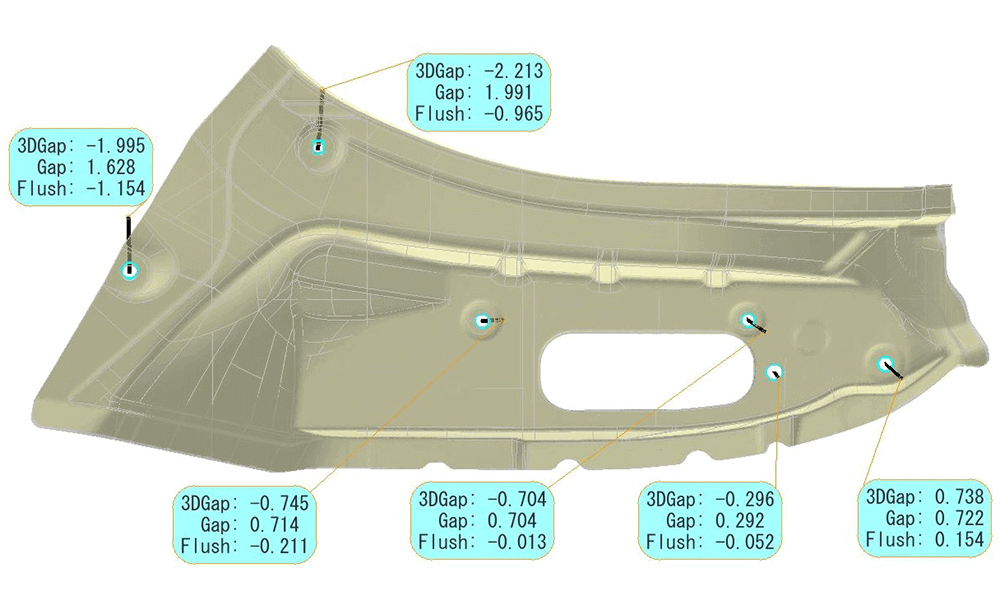

The accuracy of the center position of assembly holes and other holes in stamped products is very important. Have you had any problems with accurately extracting the central coordinates of holes by using conventional inspection methods?

spGauge can recognize circular holes, rectangular holes, and slot holes from CAD data to automatically extract and inspect them from measurement point cloud data.

This significantly shortens the inspection time in comparison with conventional inspection methods.

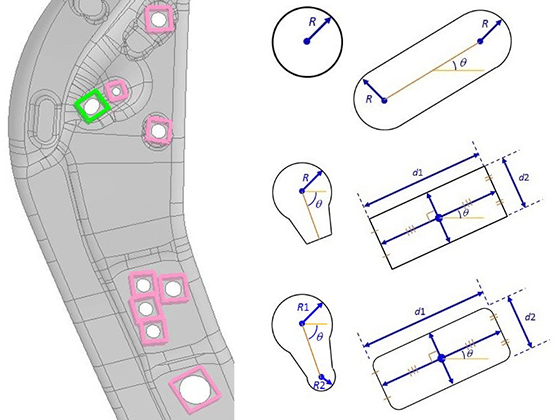

Automatic recognition of hole shapes from CAD data

Hole shapes subjected to inspection are recognized from the CAD data of the stamped product and registered.

Types of hole shapes that are automatically recognized:

- Circular holes

- Slot holes

- Rectangular holes (recognized even with rounded corners)

- Keyhole-shaped holes

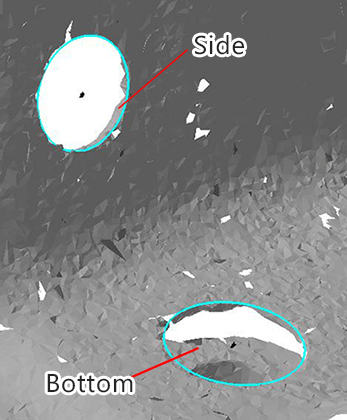

Automatically distinguishing between the point clouds of the hole bottom and the jig

If stamped products are measured by a non-contact measuring device, measured point cloud data will exist for both the hole sides and the jig. spGauge can automatically distinguish between the point cloud data for the hole sides and the jig and exclude the jig data from the target extraction to extract the exact hole edge.

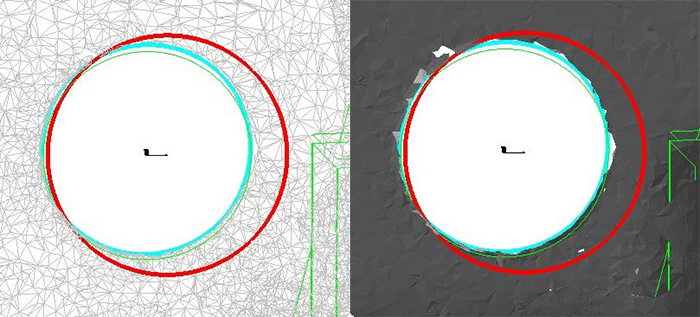

Better detection accuracy by combining non-contact measuring with spGauge

The center of the hole is calculated in contact-based measuring by measuring multiple edges of the hole. However, using a few measurement points can cause variations in the center of the hole depending on positions of measurement points.

If the production preparation process proceeds with the results of contact-based measuring that contains hole center variations, a defect may be detected on assembly causing excessive works like repeated inspection or correction.

Non-contact measuring can calculate more precise results as it measures the entire hole.

Using non-contact measuring in combination with spGauge can reduce an occurrence of rework and shorten the overall manufacturing process time.

Cyan: Results from non-contact measuring

tag : Hole inspection Press