All-in-One 3D CAD Data Translator

All-in-One 3D CAD Data Translator

spGate is a powerful tool to support the manufacturing field with features such as data translation,

defect correction, simplifying, and data downsizing.

HOME > spGate

01/05

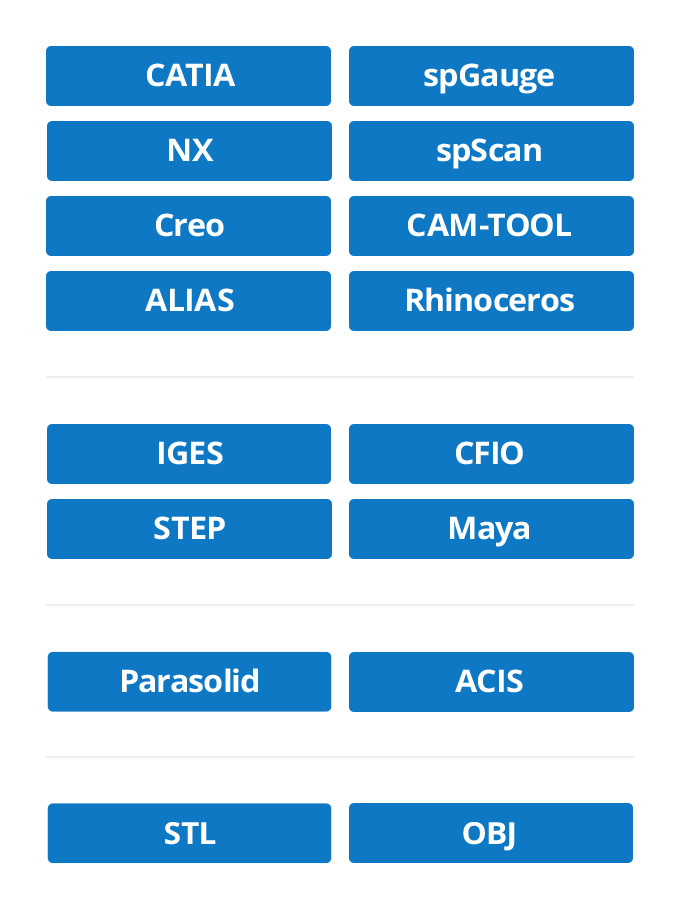

All-in-One Tool for a Wide Range of 3D CAD

Have you ever had trouble not being able to import a 3D CAD data your trading partner has sent you?

spGate includes the support for all kinds of 3D CAD data formats by default.

CATIA, NX, and Creo are mainstream in automobile and electronics makers.

ALIAS, Rhinoceros and Maya that are used in the design field.

CAM-TOOL that is used in the manufacturing sector.

Neutral files formats, IGES, JAMA-IS and STEP.

Kernel file formats, Parasolid and ACIS.

Polygon mesh formats, STL and OBJ.

All necessary file formats are included in the package and so there is no need to purchase an expensive optional license every time you have a new trading partner which leads to dealing with new file formats.

This is the 3D data translation tool with outstanding cost-performance.

02/05

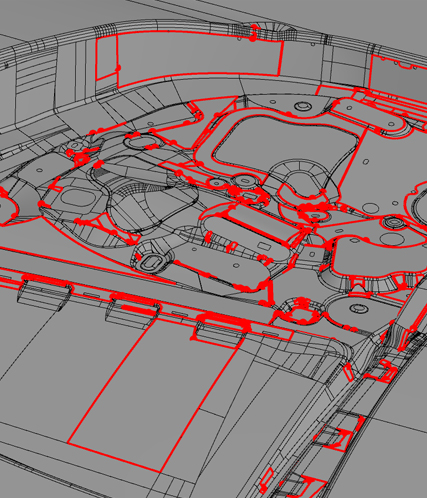

Defect Correction Feature Easier than a Generic CAD System

After importing 3D CAD data, the data will not form a solid model and so work cannot even begin...

Frequently, the main cause is the quality of the original data. With spGate, most of the defects are automatically fixed (healed). The rest of the issues, such as "a loop is intersecting itself " and "faces have a large gap in between," are simply pointed out and the optimal healing method is shown.

Unlike many generic CADs with only the bare necessities of healing features, spGate has reinforced the healing features. Allowing high quality data translation and significant reduction in man-hours spent on data correction.

03/05

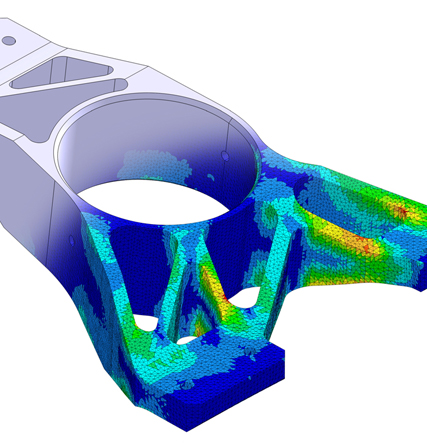

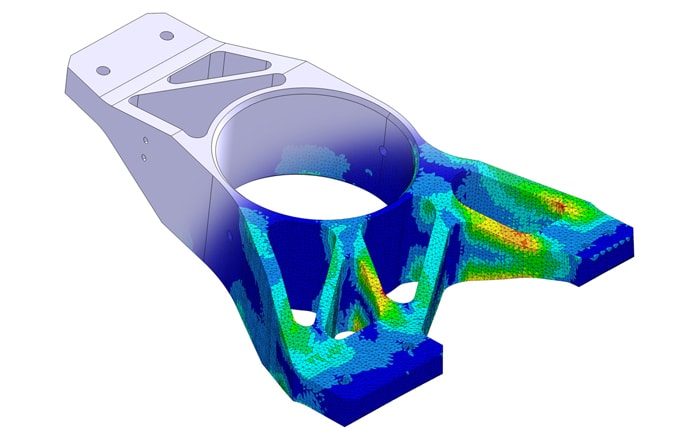

Greatly Reduce Analysis Time by Simplifying the CAD Model

When a CAD model with tiny fillets is imported into an analysis system, the number of polygons for analysis mesh increase greatly, leading to a longer analysis time.

spGate has plenty of simplification tools to prepare the CAD model for analysis.

Analysis time is reduced by removing unnecessary shapes and faces and creating the optimum CAD model for analysis.

04/05

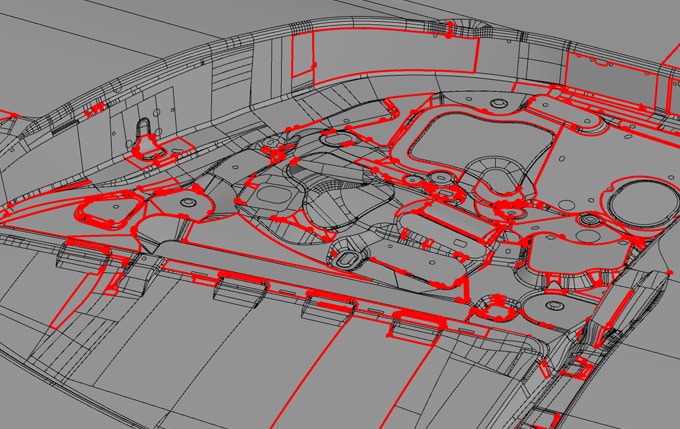

Before and After the Design changes is Made Obvious

To check for differences in design modification between before and after takes much labor.

Using spGate, you can compare two CAD models and see the modified parts in different colors for easy review.

Changes such as a shift in hole locations, existence of taper and draft angle, and changes in panel-thickness are plainly seen.

By specifying the tolerance value, even high precision checks such as in the order of submicron (0.1μm) is possible.

05/05

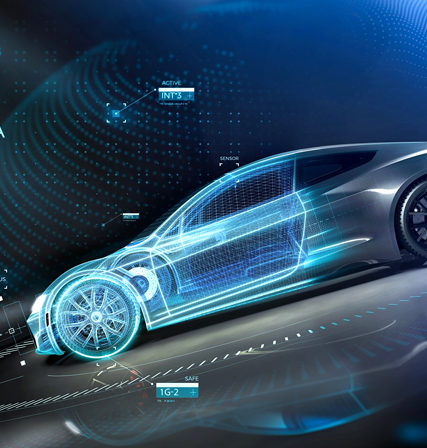

Lighten the CAD Model with 50,000 Faces to 1/100 of It.

When creating still images or movies using a 3D CAD model in CG or in the design field, the important parts are the ones seen from the outside of the 3D CAD model. With an automobile, for instance, you want to keep the exterior of the car while continuing to see the interior from the outside, as through the windows. Hidden 3D CAD model parts are typically removed individually and manually in order to reduce the rendering time. spGate automates this whole 3D CAD data downsizing process.

view more