Sophisticated Inspection Tool using Scanned Point Cloud Data

Sophisticated Inspection Tool using Scanned Point Cloud Data

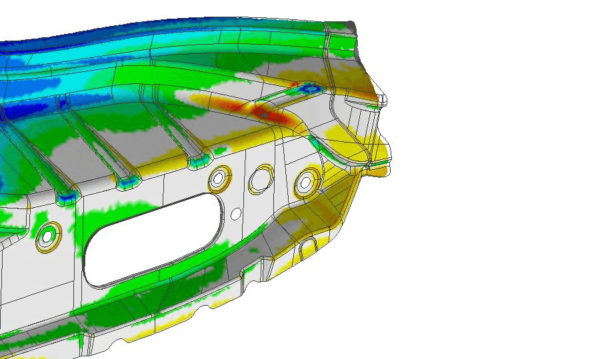

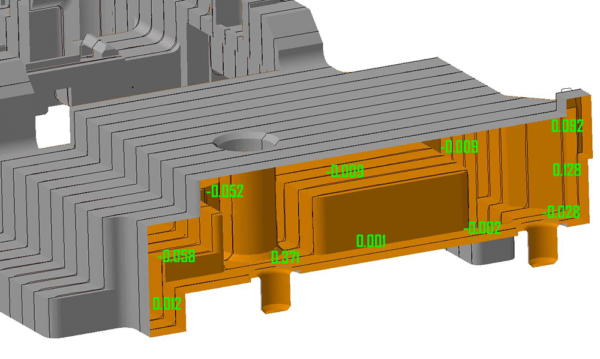

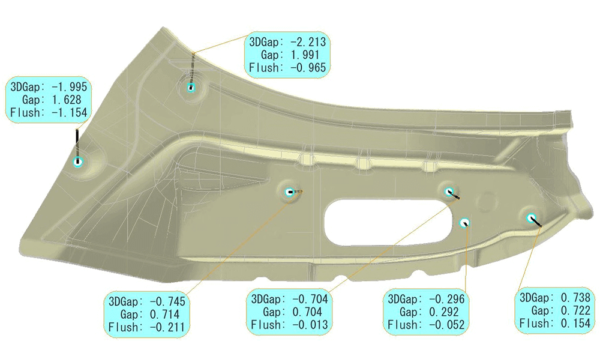

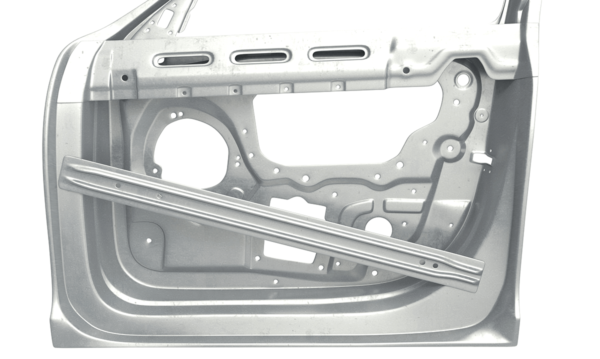

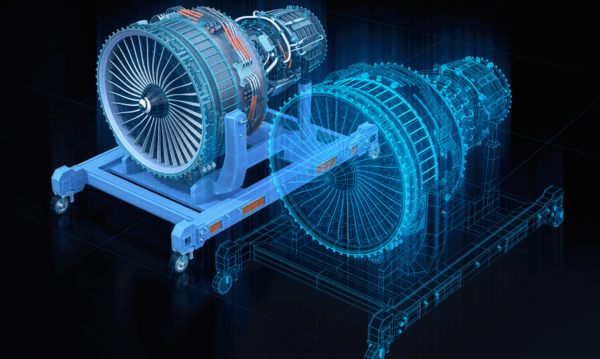

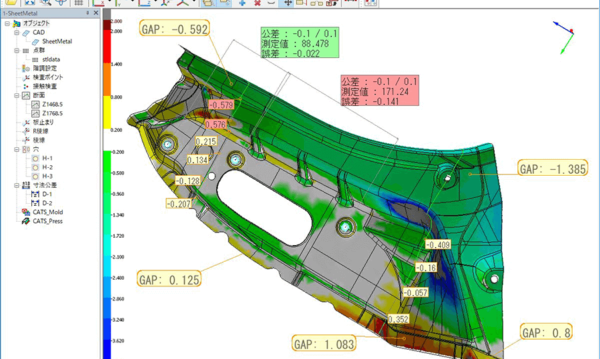

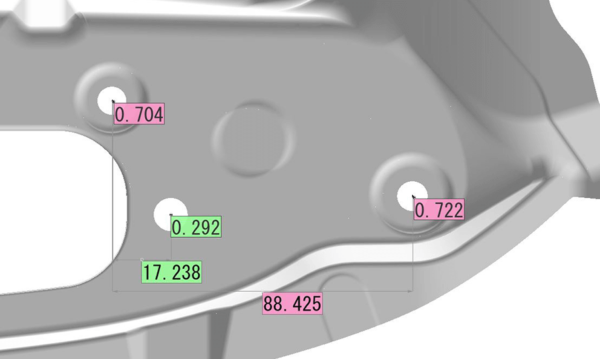

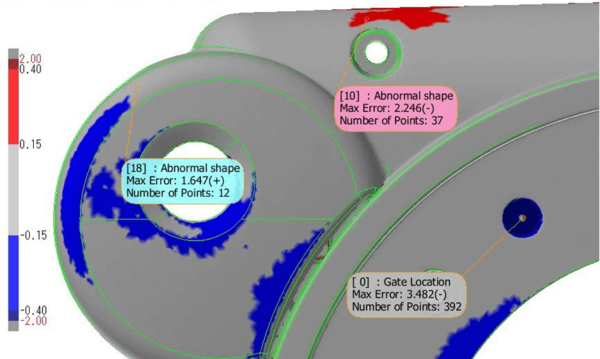

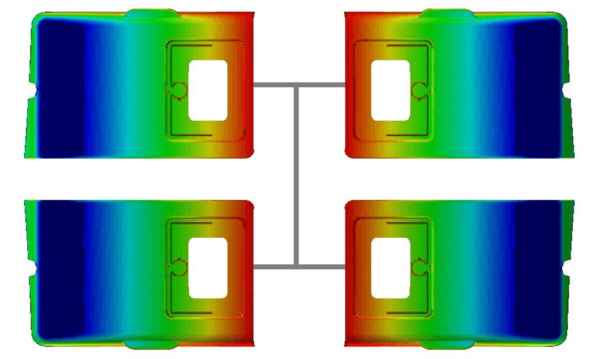

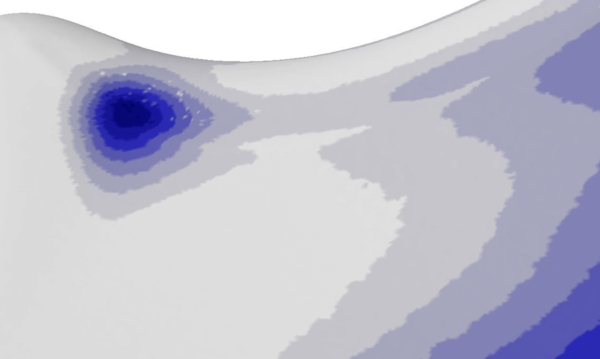

spGauge is an inspection software which uses point cloud data, measured by a 3D scanner, and CAD design data. spGauge is utilized during the production preparation stage in manufacturing as well as in the prototyping and mass production stages.

HOME > spGauge