Use cases

Sharing Inspection Results in 3D Data With Design, Analysis, Machining, and Forming Departments (Press Manufacturer)

For transmitting inspection results from the inspection department to each department including those responsible for design, analysis, machining, and forming, it takes an enormous amount of time to create images and tables.

By including 3D data in the inspection results that are sent, omission-free information can be transmitted without the need to create reports. Because all inspection results related to errors and distance dimensions from the CAD data are saved, there is no need to conduct any re-inspection and create any report even if additional inspections are required.

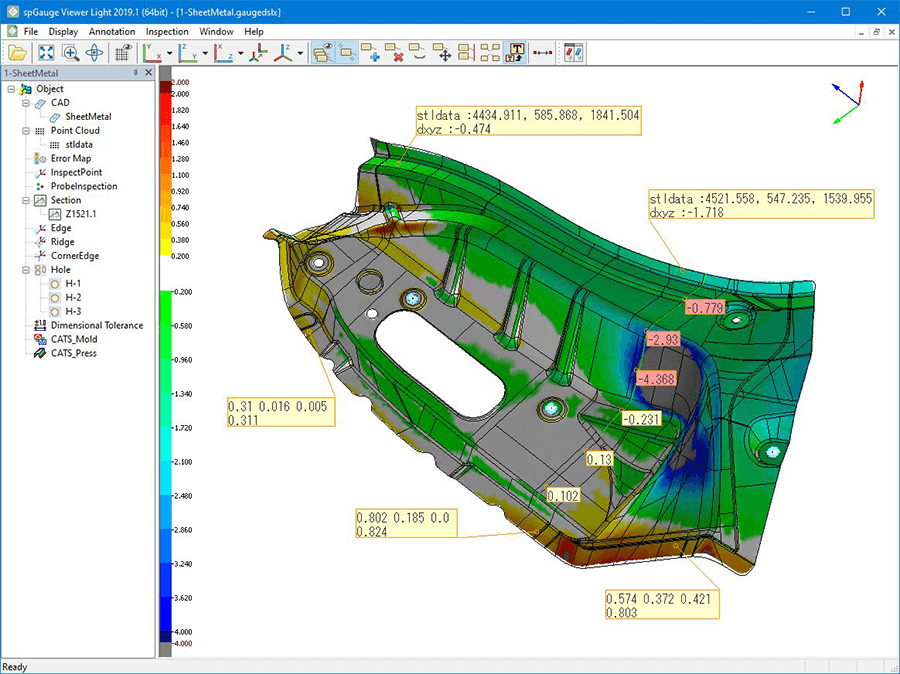

Possible to check the inspection result in 3D data

spGauge Viewer Light is a software program with a free license that makes it possible to check inspection results from spGauge.

spGauge Viewer Light data (data that can be created with spGauge itself) can be pasted into Microsoft Office (Excel, Word, and PowerPoint), and the 3D view can be manipulated – shifted and rotated – within the Office programs themselves.

Inspection results

- Error color mapping

- Section errors

- Deformation evaluation

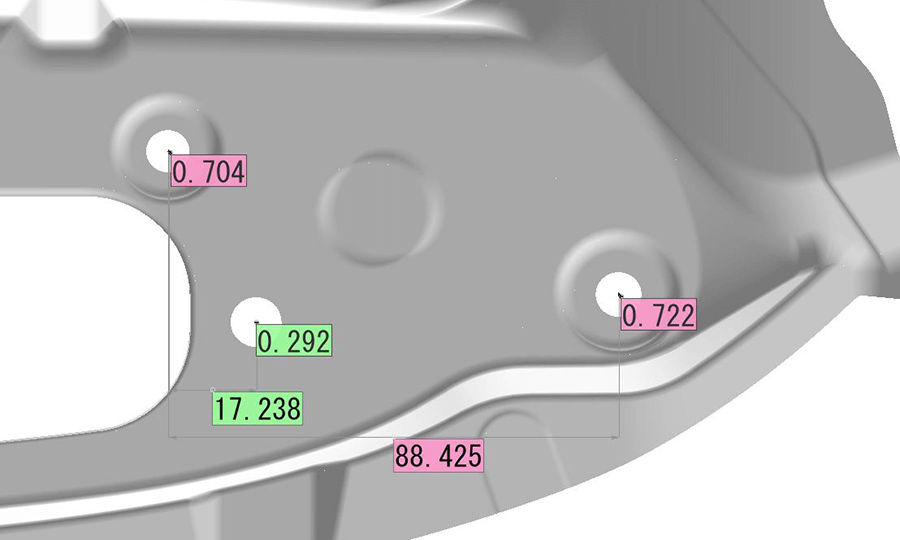

- 3D(GD&T) distance dimensions

- 2D (cross section) distance dimensions

- Angles

- Diameters