Features

Early Detection of Detective Parts of Products and Molds

Wouldn’t you like to shorten the inspecting time for stamped products, plastic products, and cast/forged products?

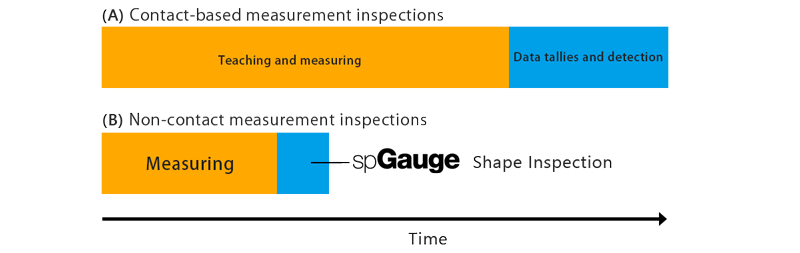

Normally, when inspecting hundreds or thousands of points with a contact measuring device, it takes an enormous amount of time for measurement teaching and data tallies of measurement time and inspection results in order to discover defects.

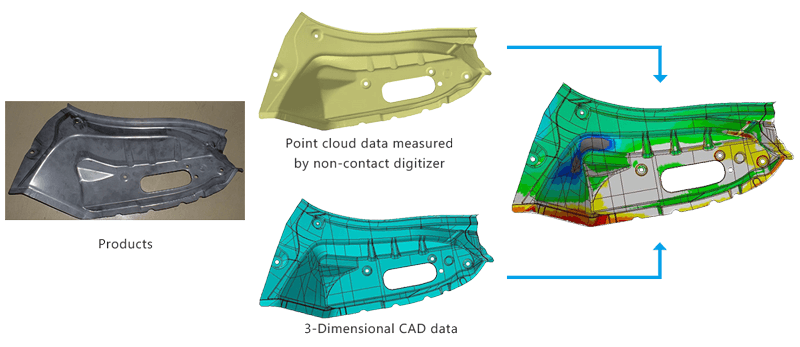

spGauge is a tool that can detect defects of product shapes and mold shapes in a short amount of time by comparing the point cloud data output from non-contact measuring devices that can quickly measure a wide range with 3D CAD data.

What is shape inspection?

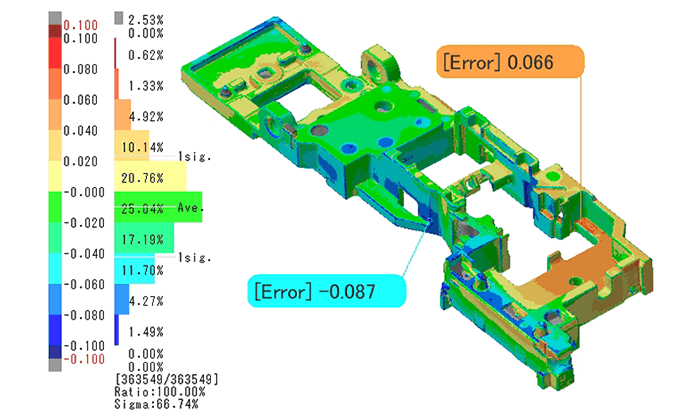

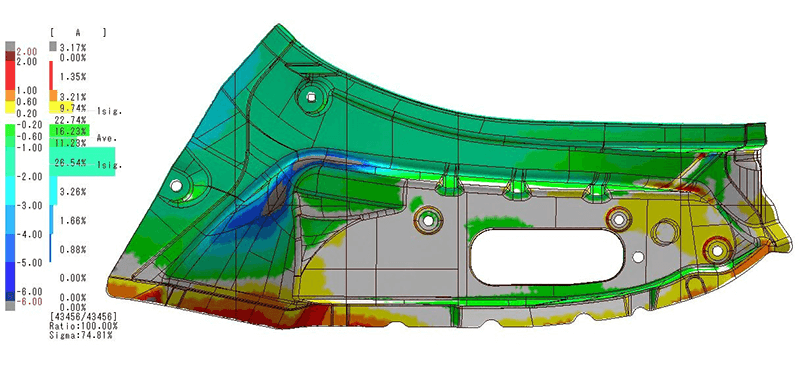

“Shape inspection” is a function to detect differences by comparing point cloud data obtained by measuring the actual product or mold with a non-contact measuring device with CAD data.

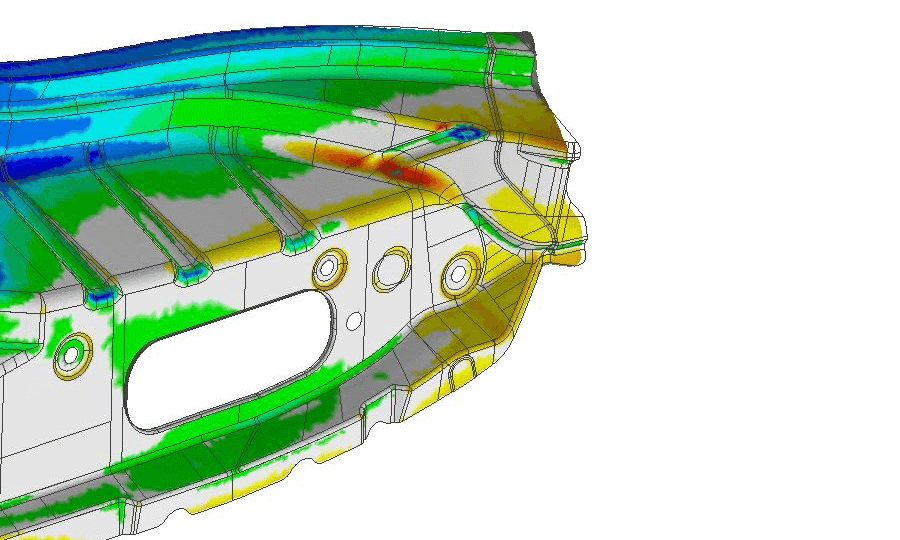

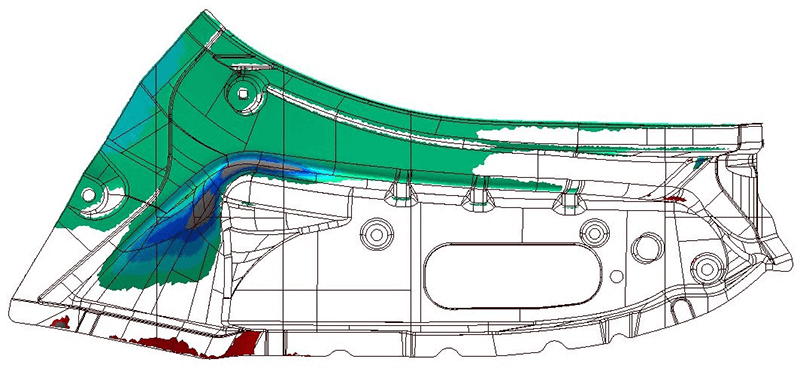

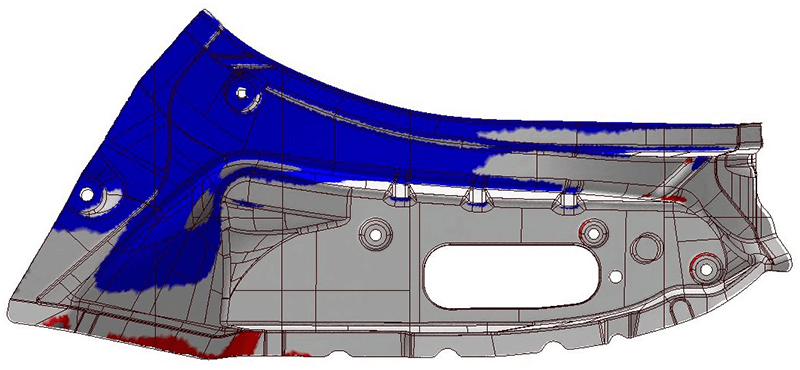

Defects can be visually detected through the display of intensity levels that represent error values in the positive or negative direction with respect to the CAD data. It is possible to highlight only erroneous areas that exceed threshold values.

Example of defect detection through shape inspection

- Stamped products

- Detection of edge warp and torsion

- Detecting locations with spring-back, spring-forward, and wall warping

- Detecting locations with frozen errors

- Plastic products

- Detecting external dimension (shrinkage factor) defects

- Detecting locations with sink marks, inadequate wall thickness, and underfilling

- Detecting boss and rib collapse and positional shifts

- Cast/forged products

- Detecting burrs due to heat cracking

- Detecting excess thickness due to die undercuts and die defects

- Detecting short-shot locations involving mold floating and sink marks

Shape inspection effectiveness

Time required to detect defects is reduced 60%!

(A) Measurements, data tallies and inspections for 1,000 locations with contact-based measurements

(B) Shape measurements made by non-contact measuring and shape inspections implemented by spGauge

tag : Shape inspection