Features

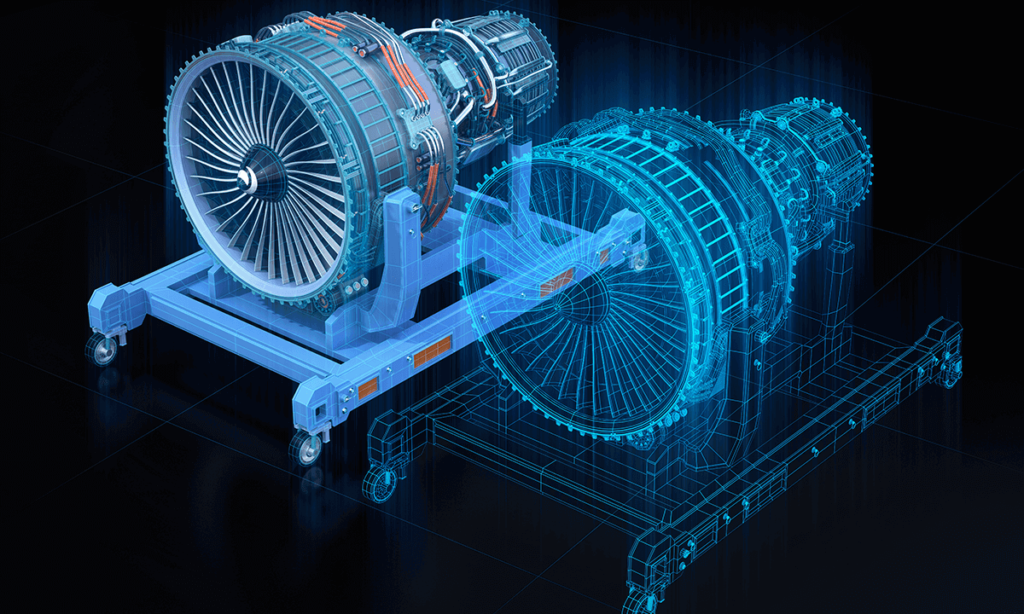

Virtual Inspections That Obviate the Need to Create Inspection Jigs

Would you like to avoid creating inspection jigs?

Inspection jigs are needed for measurement and inspection for 3D product shapes. Inspection jigs are essential for the production site, and they are indispensable for quality assurance.

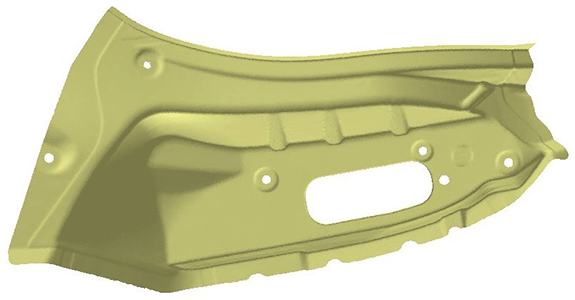

spGauge can perform virtual inspections that allow hole position variance and gap to be detected easily by aligning and comparing point cloud data for products measured by non-contact measuring devices with 3D CAD data of the inspection jig.

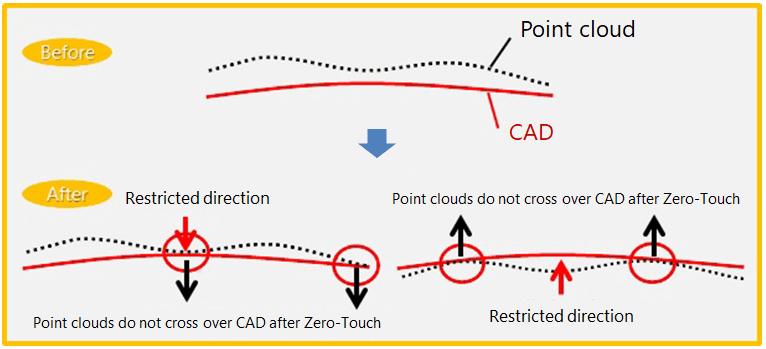

Zero-Touch Adjust

Zero-Touch Adjust is a tool to move the measurement point cloud data to the position where it touches with the CAD data when attempting to adjust the point cloud data to CAD data from specified movement or rotation direction. With this tool, a product attached to an inspection jig can be created by data only.

The advantages of using inspection jig CAD data

Using inspection jig CAD data for virtual inspections eliminates the time and expense needed to create inspection jigs. Additionally, it is easy to switch the inspection jig to the similar ones because it consists of CAD data.

tag : Alignment